the first step to conscious manufacturing: reducing

the first step to conscious manufacturing: reducing

Recycling feels good and necessary, but it should be the last resort. The most effective way to a greener manufacturing is cutting back the amount of waste we generate during the process. That means not only we have to design lasting products, but also we have to rethink the whole process all over again. Reducing is the key to a more sustainable production process and as soon as any company understands this, the revolution takes over the factory.

Reducing through conscious design

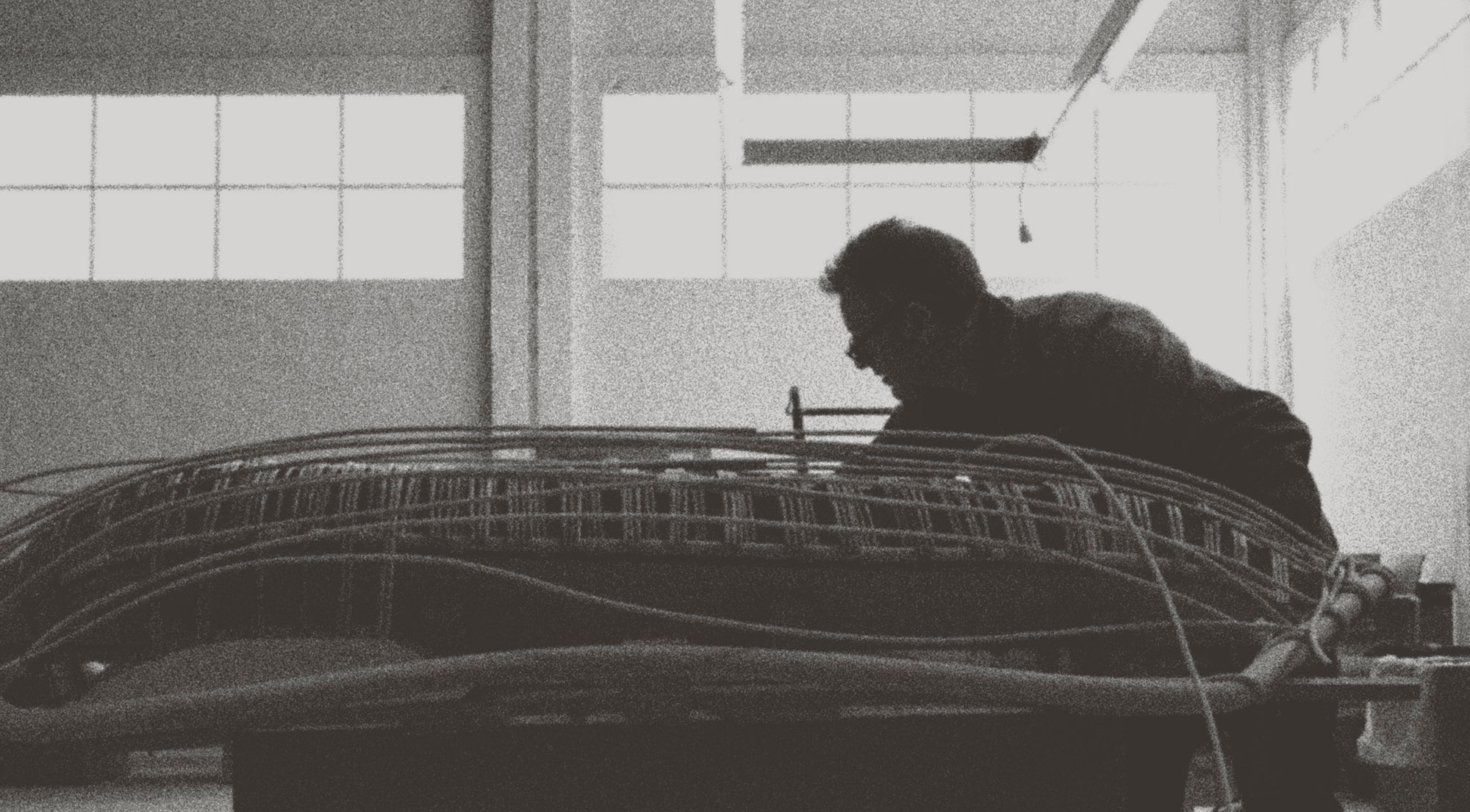

The first step to try and reduce our consumption of new raw materials, waste and pollution was embracing responsible design. In Expormim, we don’t pay much attention to fashion trends, which are closely related to fast consumption and loads of waste. We go for a different style based on timeless designs and long-lasting objects. Our aim is increasing their average lifespan. If they don’t break (or if they do, but can be repaired or recycled) and users don’t grow bored of them, we are avoiding the need of having to manufacture new products, which translates into less new raw materials, less trash and less emissions.

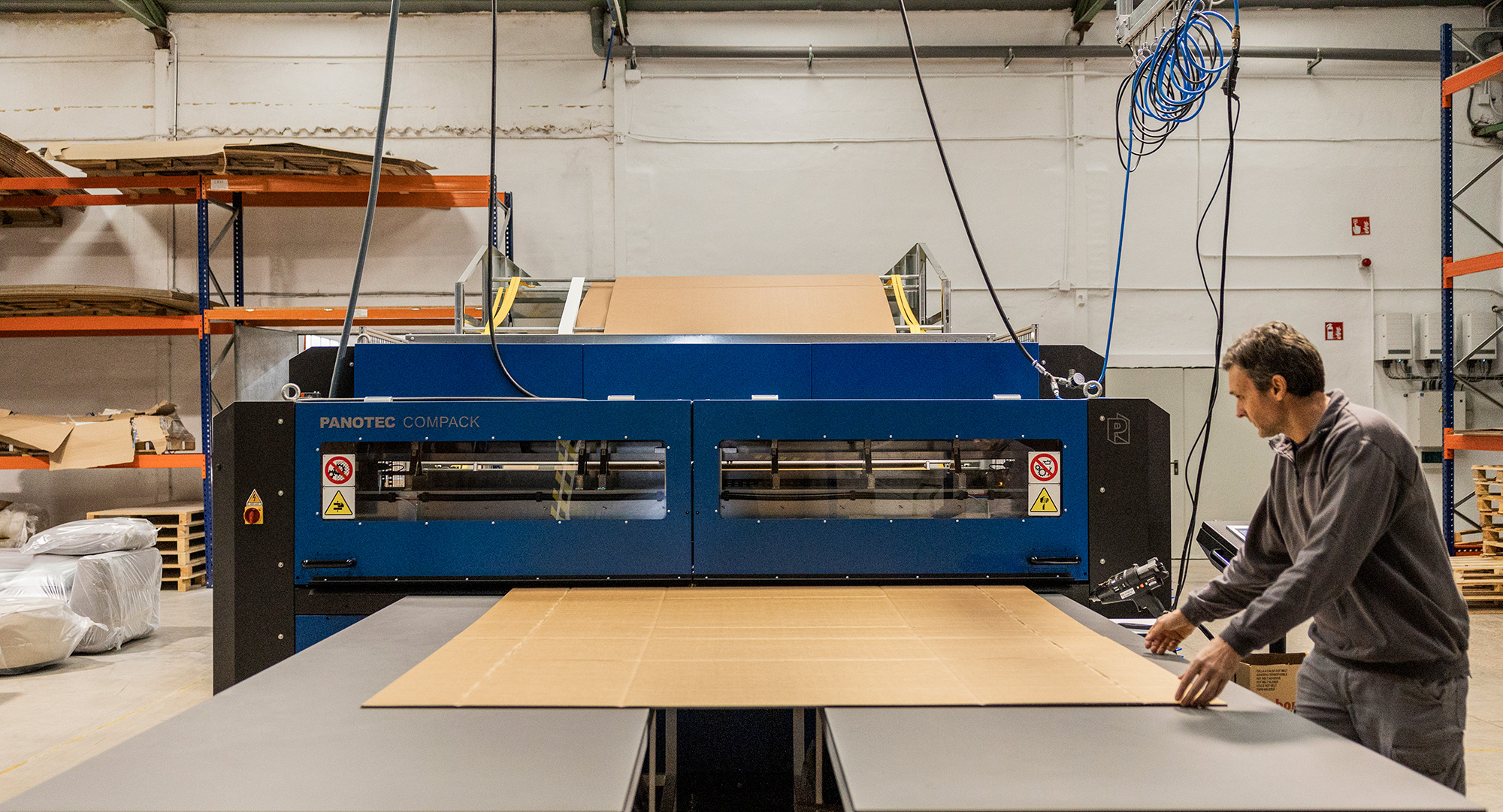

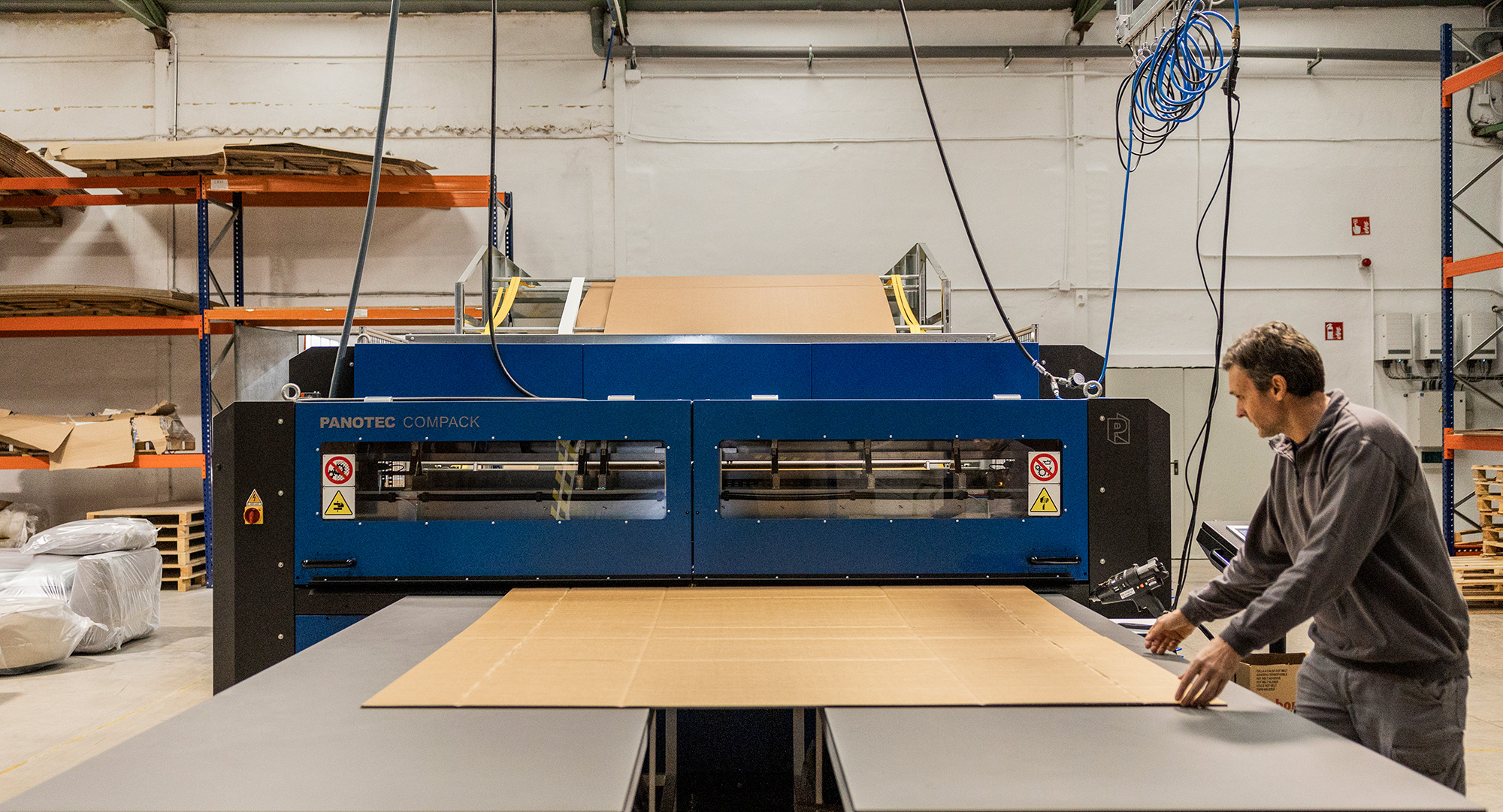

Having said that, we make a living out of manufacturing furniture and because we want to keep doing so and at the same time lower our environmental impact, we are constantly investing in new technology to help us improve the process. We have implemented digital systems that help us optimise fabric and board cutting. Precise cutting allows for a smarter utilization of textiles and wood, thus generating less waste and also increasing the quality of the final product.

The green factory

Our factory has always preserved its artisan flavour, a door to a past time where everything seems less stressful and things are handled with love and care. And yet there were aspects that we were able to modify in order to turn it into a more sustainable factory. Starting with mobility. We have replaced the fleet of diesel forklifts with electric forklifts to reduce our dependence on fossil fuels.

And we have also addressed energy consumption by installing a photovoltaic plant which is now responsible of providing 50% of our energy, a clean energy from a renewable source. Besides, all the lighting both in offices and in production areas has been replaced with LED lamps, maybe the easiest step of all, but so beneficial when it comes to energy saving.

In Expormim, we keep working everyday to reduce our ecological footprint and achieve our zero waste goal. Because we know it’s now or never.

Recycling feels good and necessary, but it should be the last resort. The most effective way to a greener manufacturing is cutting back the amount of waste we generate during the process. That means not only we have to design lasting products, but also we have to rethink the whole process all over again. Reducing is the key to a more sustainable production process and as soon as any company understands this, the revolution takes over the factory.

Reducing through conscious design

The first step to try and reduce our consumption of new raw materials, waste and pollution was embracing responsible design. In Expormim, we don’t pay much attention to fashion trends, which are closely related to fast consumption and loads of waste. We go for a different style based on timeless designs and long-lasting objects. Our aim is increasing their average lifespan. If they don’t break (or if they do, but can be repaired or recycled) and users don’t grow bored of them, we are avoiding the need of having to manufacture new products, which translates into less new raw materials, less trash and less emissions.

Having said that, we make a living out of manufacturing furniture and because we want to keep doing so and at the same time lower our environmental impact, we are constantly investing in new technology to help us improve the process. We have implemented digital systems that help us optimise fabric and board cutting. Precise cutting allows for a smarter utilization of textiles and wood, thus generating less waste and also increasing the quality of the final product.

The green factory

Our factory has always preserved its artisan flavour, a door to a past time where everything seems less stressful and things are handled with love and care. And yet there were aspects that we were able to modify in order to turn it into a more sustainable factory. Starting with mobility. We have replaced the fleet of diesel forklifts with electric forklifts to reduce our dependence on fossil fuels.

And we have also addressed energy consumption by installing a photovoltaic plant which is now responsible of providing 50% of our energy, a clean energy from a renewable source. Besides, all the lighting both in offices and in production areas has been replaced with LED lamps, maybe the easiest step of all, but so beneficial when it comes to energy saving.

In Expormim, we keep working everyday to reduce our ecological footprint and achieve our zero waste goal. Because we know it’s now or never.

Recycling feels good and necessary, but it should be the last resort. The most effective way to a greener manufacturing is cutting back the amount of waste we generate during the process. That means not only we have to design lasting products, but also we have to rethink the whole process all over again. Reducing is the key to a more sustainable production process and as soon as any company understands this, the revolution takes over the factory.

Reducing through conscious design

The first step to try and reduce our consumption of new raw materials, waste and pollution was embracing responsible design. In Expormim, we don’t pay much attention to fashion trends, which are closely related to fast consumption and loads of waste. We go for a different style based on timeless designs and long-lasting objects. Our aim is increasing their average lifespan. If they don’t break (or if they do, but can be repaired or recycled) and users don’t grow bored of them, we are avoiding the need of having to manufacture new products, which translates into less new raw materials, less trash and less emissions.

Having said that, we make a living out of manufacturing furniture and because we want to keep doing so and at the same time lower our environmental impact, we are constantly investing in new technology to help us improve the process. We have implemented digital systems that help us optimise fabric and board cutting. Precise cutting allows for a smarter utilization of textiles and wood, thus generating less waste and also increasing the quality of the final product.

The green factory

Our factory has always preserved its artisan flavour, a door to a past time where everything seems less stressful and things are handled with love and care. And yet there were aspects that we were able to modify in order to turn it into a more sustainable factory. Starting with mobility. We have replaced the fleet of diesel forklifts with electric forklifts to reduce our dependence on fossil fuels.

And we have also addressed energy consumption by installing a photovoltaic plant which is now responsible of providing 50% of our energy, a clean energy from a renewable source. Besides, all the lighting both in offices and in production areas has been replaced with LED lamps, maybe the easiest step of all, but so beneficial when it comes to energy saving.

In Expormim, we keep working everyday to reduce our ecological footprint and achieve our zero waste goal. Because we know it’s now or never.

the first step to conscious manufacturing: reducing

the first step to conscious manufacturing: reducing

Recycling feels good and necessary, but it should be the last resort. The most effective way to a greener manufacturing is cutting back the amount of waste we generate during the process. That means not only we have to design lasting products, but also we have to rethink the whole process all over again. Reducing is the key to a more sustainable production process and as soon as any company understands this, the revolution takes over the factory.

Reducing through conscious design

The first step to try and reduce our consumption of new raw materials, waste and pollution was embracing responsible design. In Expormim, we don’t pay much attention to fashion trends, which are closely related to fast consumption and loads of waste. We go for a different style based on timeless designs and long-lasting objects. Our aim is increasing their average lifespan. If they don’t break (or if they do, but can be repaired or recycled) and users don’t grow bored of them, we are avoiding the need of having to manufacture new products, which translates into less new raw materials, less trash and less emissions.

Having said that, we make a living out of manufacturing furniture and because we want to keep doing so and at the same time lower our environmental impact, we are constantly investing in new technology to help us improve the process. We have implemented digital systems that help us optimise fabric and board cutting. Precise cutting allows for a smarter utilization of textiles and wood, thus generating less waste and also increasing the quality of the final product.

The green factory

Our factory has always preserved its artisan flavour, a door to a past time where everything seems less stressful and things are handled with love and care. And yet there were aspects that we were able to modify in order to turn it into a more sustainable factory. Starting with mobility. We have replaced the fleet of diesel forklifts with electric forklifts to reduce our dependence on fossil fuels.

And we have also addressed energy consumption by installing a photovoltaic plant which is now responsible of providing 50% of our energy, a clean energy from a renewable source. Besides, all the lighting both in offices and in production areas has been replaced with LED lamps, maybe the easiest step of all, but so beneficial when it comes to energy saving.

In Expormim, we keep working everyday to reduce our ecological footprint and achieve our zero waste goal. Because we know it’s now or never.

Recycling feels good and necessary, but it should be the last resort. The most effective way to a greener manufacturing is cutting back the amount of waste we generate during the process. That means not only we have to design lasting products, but also we have to rethink the whole process all over again. Reducing is the key to a more sustainable production process and as soon as any company understands this, the revolution takes over the factory.

Reducing through conscious design

The first step to try and reduce our consumption of new raw materials, waste and pollution was embracing responsible design. In Expormim, we don’t pay much attention to fashion trends, which are closely related to fast consumption and loads of waste. We go for a different style based on timeless designs and long-lasting objects. Our aim is increasing their average lifespan. If they don’t break (or if they do, but can be repaired or recycled) and users don’t grow bored of them, we are avoiding the need of having to manufacture new products, which translates into less new raw materials, less trash and less emissions.

Having said that, we make a living out of manufacturing furniture and because we want to keep doing so and at the same time lower our environmental impact, we are constantly investing in new technology to help us improve the process. We have implemented digital systems that help us optimise fabric and board cutting. Precise cutting allows for a smarter utilization of textiles and wood, thus generating less waste and also increasing the quality of the final product.

The green factory

Our factory has always preserved its artisan flavour, a door to a past time where everything seems less stressful and things are handled with love and care. And yet there were aspects that we were able to modify in order to turn it into a more sustainable factory. Starting with mobility. We have replaced the fleet of diesel forklifts with electric forklifts to reduce our dependence on fossil fuels.

And we have also addressed energy consumption by installing a photovoltaic plant which is now responsible of providing 50% of our energy, a clean energy from a renewable source. Besides, all the lighting both in offices and in production areas has been replaced with LED lamps, maybe the easiest step of all, but so beneficial when it comes to energy saving.

In Expormim, we keep working everyday to reduce our ecological footprint and achieve our zero waste goal. Because we know it’s now or never.

Recycling feels good and necessary, but it should be the last resort. The most effective way to a greener manufacturing is cutting back the amount of waste we generate during the process. That means not only we have to design lasting products, but also we have to rethink the whole process all over again. Reducing is the key to a more sustainable production process and as soon as any company understands this, the revolution takes over the factory.

Reducing through conscious design

The first step to try and reduce our consumption of new raw materials, waste and pollution was embracing responsible design. In Expormim, we don’t pay much attention to fashion trends, which are closely related to fast consumption and loads of waste. We go for a different style based on timeless designs and long-lasting objects. Our aim is increasing their average lifespan. If they don’t break (or if they do, but can be repaired or recycled) and users don’t grow bored of them, we are avoiding the need of having to manufacture new products, which translates into less new raw materials, less trash and less emissions.

Having said that, we make a living out of manufacturing furniture and because we want to keep doing so and at the same time lower our environmental impact, we are constantly investing in new technology to help us improve the process. We have implemented digital systems that help us optimise fabric and board cutting. Precise cutting allows for a smarter utilization of textiles and wood, thus generating less waste and also increasing the quality of the final product.

The green factory

Our factory has always preserved its artisan flavour, a door to a past time where everything seems less stressful and things are handled with love and care. And yet there were aspects that we were able to modify in order to turn it into a more sustainable factory. Starting with mobility. We have replaced the fleet of diesel forklifts with electric forklifts to reduce our dependence on fossil fuels.

And we have also addressed energy consumption by installing a photovoltaic plant which is now responsible of providing 50% of our energy, a clean energy from a renewable source. Besides, all the lighting both in offices and in production areas has been replaced with LED lamps, maybe the easiest step of all, but so beneficial when it comes to energy saving.

In Expormim, we keep working everyday to reduce our ecological footprint and achieve our zero waste goal. Because we know it’s now or never.